Lab Station: Buffer tank

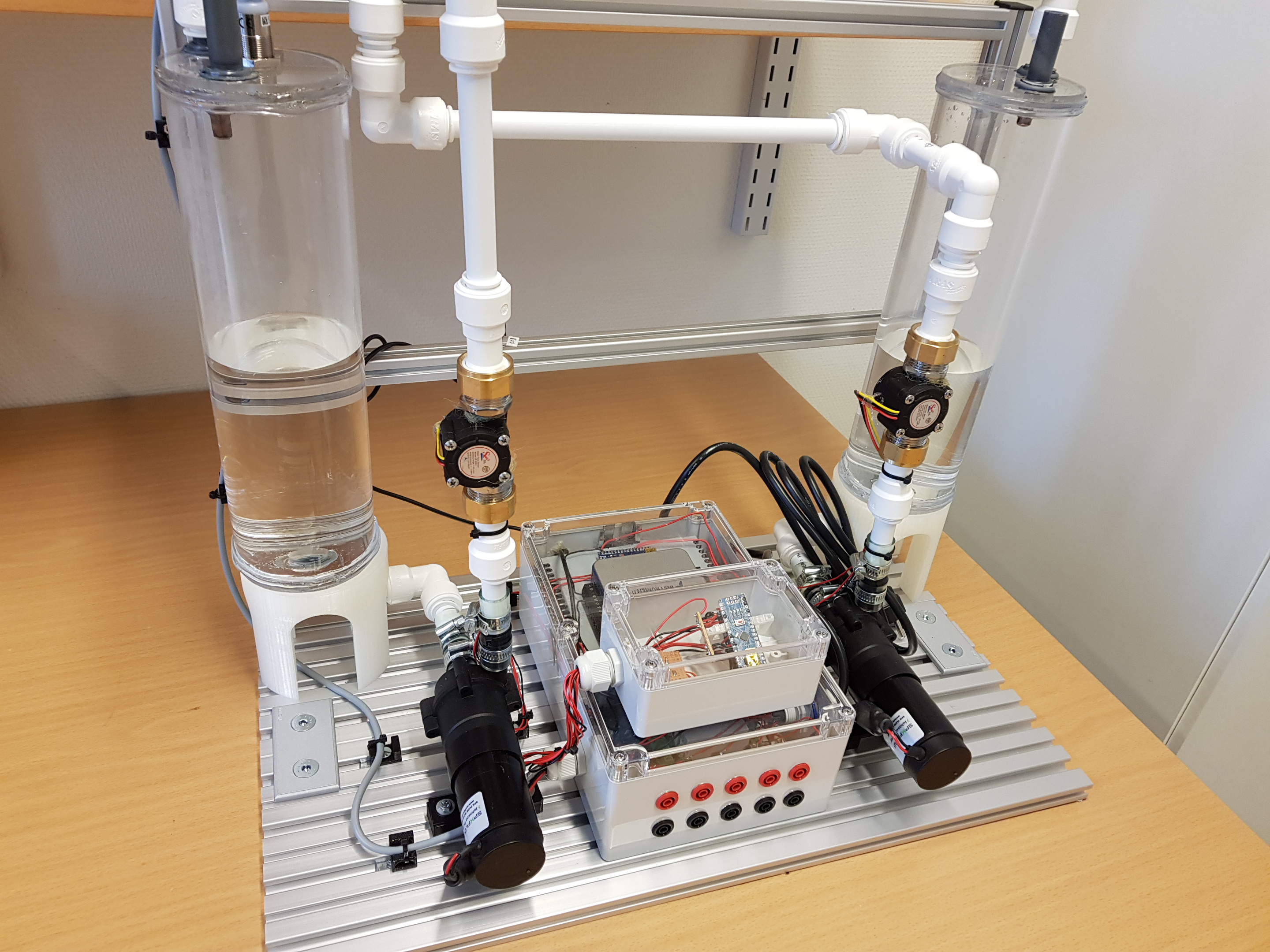

University of South-Eastern Norway (campus Porsgrunn) has 18 laboratory

buffer tanks, see Figure 1. The tanks are used in control courses in both

bachelor and master programmes in technology.

Figure 1: Buffer tank

Applications

Averaging level control is an important

part of several process systems. Some important practical examples are:

·

The equalization

or buffer magazine at the inlet of a wasteater treatment plant.

·

Oil/water

separators in the oil industry.

·

Water magazines

in hydropower systems.

Both the equalization magazine and the

separator can here be regarded as liquid buffer tanks. In both examples, the

level should be compliant to flow variations so that variations in the inflow

are damped through the tank, making the outflow considerably smoother than

the inflow. Smoother outflow is advantageous for the subsequent processes,

e.g. for the biological treatment processes and the oil production. The level

controller must be tuned for compliant (or soft, or sluggish) level control

so that the volume of the tank can absorb the inlet variations.

Technical description

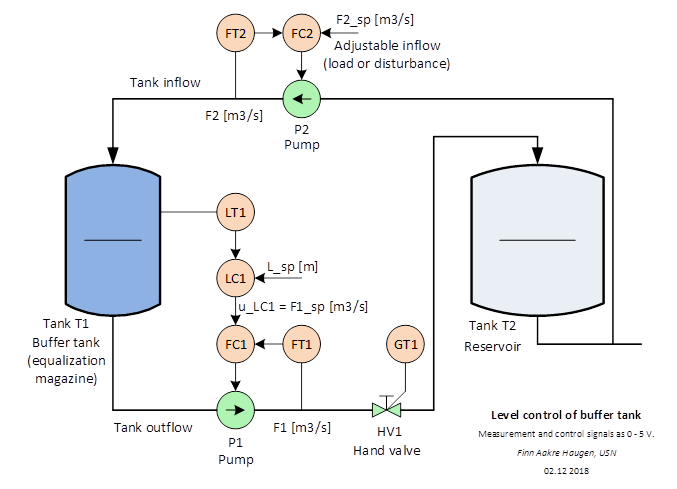

Figure 2 shows a piping and instrumentation diagram (P&I D) of the

tank including a level control system.

Figure 2: Piping and

instrumentation diagram (P&I D) of the buffer tank a level control

system.

The measurement signals (analog inputs) from the sensors LT1, FT1 and FT2

are voltage signals in the range 0 – 5 V.

The control signals (analog outputs) to the actuators pump P1and pump P2

are voltage signals in the range 0 – 5 V.

A built-in NI USB-6001 IO device handles the IO. This IO device can be

connected to a PC with a USB cable.

As an alternative to using the NI USB-6001 IO device, there are terminals

on the rig for direct analog IO.

Technical information

To appear.

Video presenting the buffer tank

To appear.

Level controller

The control signal generated by the level controller is a demanded

outflow:

u = F_out

The level controller may be a PI controller or some other controller.

Mathematical model

Mass balance of the water in the tank:

rho*A*dh_dt = rho*F_in – rho*F_out

where:

·

h [cm] is the water level in the tank.

·

F_in [cm^3/s] is water inflow.

·

F_out [cm^3/s] is water outflow.

·

A [cm^2] is cross-sectional area of tank.

·

rho [g/cm^3] is water density.

Cancelling out rho and solving for dh_dt gives the

dh_dt = (1/A)*(F_in - F_out)

Nominal values and ranges:

·

h_nom = 15. Range: 0 - 30.

·

F_in_nom = 50. Range: 0 - 100.

·

F_out_nom = 50. Range: 0 - 100.

·

A = 56.7.

·

rho = 1 (but its value is not needed).

How realize white noise in a simulator

If you want to include white process disturbance (noise) or white measurement

noise in a simulator of the buffer tank programmed in Python, you may use the

following information about how to generate uniformly distributed white noise

with specified standard deviation:

std_noise

= 0.01 # Standard deviation. 0.01 is

an example value. Select any other.

var_noise = std_noise**2 # Variance

ampl_noise = np.sqrt(3*var_meas_noise)

# Ampl of uniformly dist white noise. (np is numpy.)

v_k = np.random.uniform(-ampl_noise, ampl_noise, 1) # The noise (point value)

About

The project has been initiated by BSc Olav Vangen and Prof. Finn Aakre Haugen.

The construction as been accomplished by Olav Vangen, Cecilie Gløsmyr,

Fredrik Hansen, BSc Marius Bergflødt, and students at Skogmo high school.

Updated

21 February 2020 by Finn Aakre Haugen.

E-mail: finn.haugen@usn.no.

|