Cascade Control

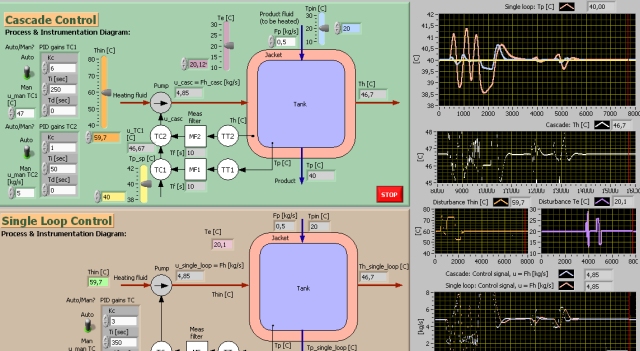

Snapshot of the front panel of the simulator:

- What is needed to run the the simulator? Read to get most recent information!

- Tips for using the simulator.

- The simulator: cascade_control_temperature.zip (unzip, and open cascade_control_temperature.exe). Note: The present version of this simulator requires LabVIEW Runtime Engine 2017 to be installed on your PC.

Description of the simulated systems

In this simulator two temperature control systems of a liquid tank heated with hot liquid in a jacket are simulated in parallel (i.e. simultaneously), so that the benefits of cascade control are easily observed:

- A cascade control system with temperature control of both the tank and the jacket.

- A single-loop control system with temperature control of the tank only.

Both control systems are excited by the same temperature setpoint and the same disturbances.

In both control systems the process to be controlled is given by the following model based on energy balances:

dTp/dt=[cp*Fp*(Tpin-Tp)+Uhp*(Th-Tp)]/(cp*dp*Vp)

dTh/dt=[ch*Fh*(Thin-Th)-Uhp*(Th-Tp)+Ueh*(Te-Th)]/(ch*dh*Vh)

where Tp is product liquid temperature, Th is heating liquid temperature, cp and ch are specific heat capacities, Fp and Fh are flows, Tpin and Thin are inlet temperatures, Vp and Vh are volumes of jacket and tank respectively, Te is environmental temperature, dp and dh are liquid densities, Uhp and Ueh are heat transfer coefficients between jacket and tank, and between jacket and enviroment (air) respectively. (All parameter values are available from the front panel of the simulator.)

To account for unmodelled dynamics, a pure time delay is added to the measured temperatures Tp and Th.

The measurements of Tp and Th are fed to measurement lowpass filters with time constant Tf.

Aims

The aims of the tasks given below are

- to give experience in tuning the controller parameters,

- to demonstrate the situations where cascade control gives better control than single-loop control,

- to demonstrate the situations where cascade control does not give better control than single-loop control.

Motivation

Cascade control is a common control structure in both process control systems and in servomechanisms. In process control cascade control is used for temperature control, level control, pressure control, and quality control. These are the primary control loops, while the secondary loop typically performs flow control or pressure control.

In servomechanisms the primary loops perform positional control or speed control, while the secondary loop typically performs speed control (in a primary positional loop), or current control (in electrical servomechanisms).

Cascade control can give a much better compensation for disturbances than single loop control can do.

Tasks

In the tasks below the starting point is that the process is in it's nominal operating point which is characterized as follows:

- The product temperature setpoint is 40 C.

- The product inlet temperature is 20 C.

- The product inlet flow is 0.5 kg/s.

- The environmental temperature is 20 C.

- The heating liquid inlet temperature is 60 C.

- Checking the present controller settings:

The controllers have already been tuned for fast and stable control, but you should check if the present PI settings are ok.

Excite the control systems with a small step in the set-point (a step amplitude of 0.5 C is appropriate here). Is the stability of the control loops ok (just make a qualitative assessment)?

(You may of course tune the controllers yourself, but this is not a prerequisite for the tasks below.)

- Cascade

control versus single-loop control:

- Disturbance compensation:

Compare the two control systems with respect to their ability to

compensate for the following disturbance changes:

- Changes in the heating liquid inlet temperature, Th_in (adjust Th_in freely via the slider). Is cascade control significantly better than single-loop control? Why/why not?

- Changes in the environmental temperature, Te. Is cascade control significantly better than single-loop control? Why/why not?

- Changes in the product liquid inlet temperature, Tpin. Is cascade control significantly better than single-loop control? Why/why not?

Observe also how the control variable works in the two control systems. In which of them is the control variable working most actively?

- Setpoint tracking: Make step change of the temperature setpoint, Tpsp. Is cascade control significantly better than single-loop control? Why/why not?

- Disturbance compensation:

Compare the two control systems with respect to their ability to

compensate for the following disturbance changes:

Updated 05. March 2025. Developed by Finn Haugen. E-mail: finn@techteach.no.