YOU - The Controller!

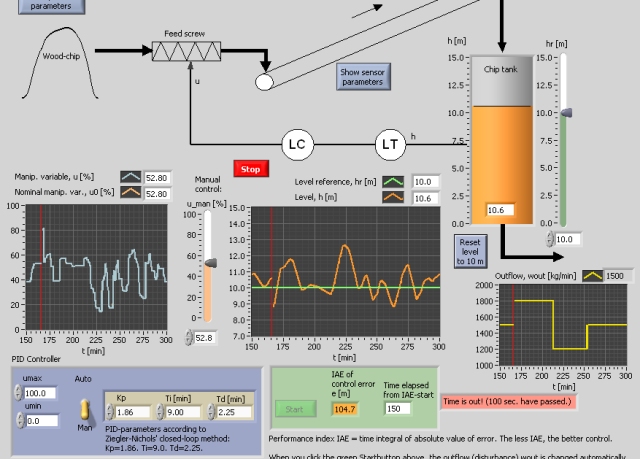

Snapshot of the front panel of the simulator:

- What is needed to run the the simulator? Read to get most recent information!

- Tips for using the simulator.

- The simulator: you_the_controller.exe . The simulator runs immediately after the download by clicking Open in the download window. Alternatively, you can first save a copy of the exe-file on any directory (folder) on your PC and then run the exe-file, which starts the simulator.

Description of the simulated system

A level control for a wood chip tank is simulated. The level control system is (quite) similar to a real control system at Tofte Södra Cell in Norway. (As of 2017, the factory has been closed - not due to poor level control, however.)

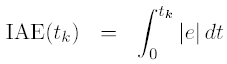

To quantize the performance of the controller the IAE performance index (Integral of Absolute value of control Error) is calculated continuously:

We can say that the less IAE index, the better control. However, the IAE index does not express the control usage, so it may happen that the control usage is abrupt, causing wear on mechanical actuatorsas valves, motors and pumps.

When you click the IAE button on the front panel of the simulator, the chip outflow (disturbance) wout and the level setpoint are automatically changed at specific points of time, and the IAE calculation is started to be running for 250 minutes (simulation time). The less IAE you obtain, the better controller you are!

Aim

One aim is that you experience how a controller works by trying to being a controller yourself, and to observe that it may be difficult to control a process manually equally well as an automatic PI(D) controller does.

Motivation

Many industrial processes may be controlled manually, i.e. by an operator, but it can be useful to experience that a PI controller can do the job better - and not the least important: to do it automatically.

Tasks

Follow the instructions down to the left on the front panel of the simulator.

- What is the IAE value with the PID controller in action? (You can use the default PI settings in the simulator.)

- What IAE value do you achieve by manually controlling the process? (You may of course try several times.)

Updated 3 September 2017. Developed by Finn Haugen. E-mail: finn@techteach.no.